Part 2: Planning for a Computer Room Air Handler

In Part 1 of Keep Your Data Center Cool with Kele, we outlined a variety of strategies to remove heat from a data center. Doing so is critical to successful 24/7 operation, lest electrical components malfunction, servers exceed their maximum temperature, and equipment go offline. The most common solution is a Computer Room Air Conditioner or Air Handler. (These are CRAC and CRAH, respectively. We will use CRAH in this article).

Essentially, a CRAH blows cold air in a set path to remove hot air from the area using a variety of devices keep everything flowing properly. Internal heat exchangers connect to refrigeration systems or water chillers to remove heat. Filters remove dust while fans circulate and distribute the air. A CRAH may also include humidifiers or dehumidifiers to help control static electricity in the air.

While some data center server rooms are positioned on a raised floor with a CRAC underneath, a CRAH is typically located overhead and blows cool air downward. If your data center employs a hot aisle/cold aisle strategy (summarized in Part 1), you have options. The CRAH can be placed to send cool air down directly to the cold aisle or above the hot aisle where it will force hot air up to be cooled through the system.

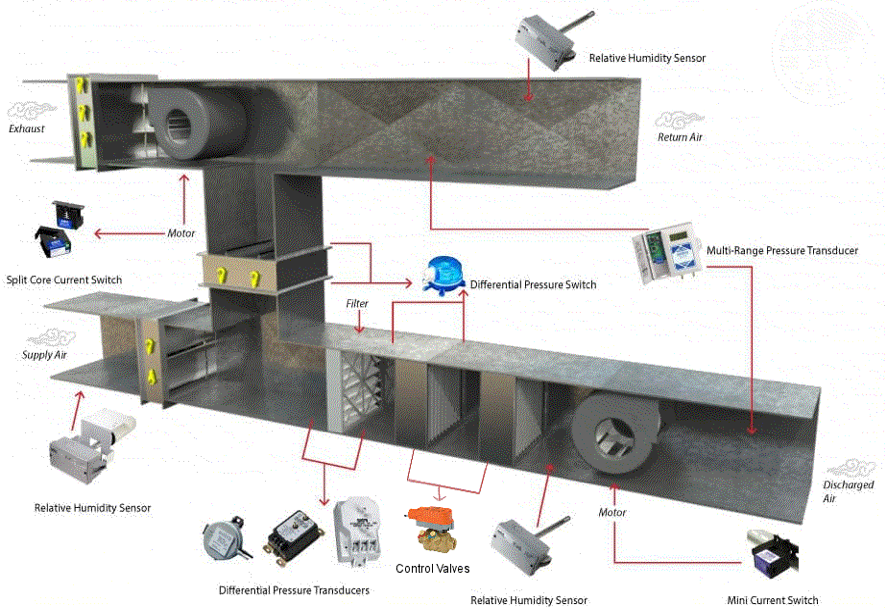

As your project engineer works through the CRAH system plan, he/she must also consider the list of components essential to controlling the system and monitoring the surrounding environment. These are as important as the system itself. See below for a breakout of typical CRAH system components. Each is listed with a brief description of its purpose.

Breakout of a Typical Air Handling Unit and its Components

CRAH Components

- Control Dampers – regulate the amount of air in CRAH.

- Direct Coupled Spring Return Actuators – open and close dampers.

- Outside Airflow Measuring System – measures the amount of airflow in the CRAH.

- Differential Pressure Switch – senses difference in pressure between two points.

- Duct Temperature Sensor – measures the temperature at the sensor location.

- Chill Water/Hot Water Valves (zone, ball globe valves) – regulate water flow through a coil.

- Current Switch – shows on/off Status of fans, pumps, and motors.

- Low-Limit (freezestat) Detector – protects equipment on low temperatures.

- Duct High-Temperature Limit (firestat) Detector – protects equipment on high temperatures.

- Airflow Measuring Station – measures the amount of airflow in the CRAH.

- Differential Pressure Transmitters – sense the difference in pressure between two points and produces an output signal.

- Duct Humidity Sensor – measures relative humidity at the sensor location

- Duct Smoke Detectors & Remote Accessories – shut down the unit when the detector senses smoke.

- Air Velocity Measurement – used to control air velocity to balance out pressure fluctuations

- Differential Pressure Gauge – visual indication of the difference between two pressure points. (e.g., measures pressure on both sides of an air filter)

Kele can equip you with every product you need to monitor and control temperature, humidity, and pressure, and to manage airflow. We can also provide parts to monitor compressor and chiller run time to track energy consumption. Kele’s project services team will help you think through your entire project BOM on the front end and select the right components for your system. If you have questions about anything you see above, our technical services team can provide answers

Over the past few months, we covered the rapid growth and permanence of data centers—including the need for speed when building them. We summarized a variety of cooling strategies to remove heat and keep equipment and servers online. And above we outlined the inner workings and essential components to the most common cooling strategy.

Hopefully, you are better equipped with the information you need for cooling your data center. Kele is here with the service and products you need to make it happen. Contact us today. And stay cool.