Our technical panel team has over 100 combined years of experience in designing and assembling custom panels. As a value-added service to our customers, our team completes an accuracy review of each schematic panel diagram checking for potential errors and omissions. Ninety-five percent (95%) of the time, if an issue is discovered, the mishap occurs in one of two areas.

Our technical panel team has over 100 combined years of experience in designing and assembling custom panels. As a value-added service to our customers, our team completes an accuracy review of each schematic panel diagram checking for potential errors and omissions. Ninety-five percent (95%) of the time, if an issue is discovered, the mishap occurs in one of two areas.

Customer Issue #1: Sizing

Incorrect component dimensions are used to determine enclosure specifications and panel layouts. When this occurs, it slows down assembly and can delay installation at the job site as alternative solutions are sourced.

Kele Solution to Issue #1

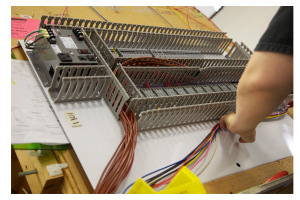

Allow Kele to build your custom panels. Kele’s Custom Kele Panel Shop scales your project and panel needs for you. We use customized software and magnetic boards to scale dimensions while creating a mock assembly. Sample photos are then sent to you for review prior to assembly.

Customer Issue #2: Typos in Circuitry

Faulty connections or direct shorts are often the results of a diagram containing misprints including errors in method, wiring techniques, or circuitry.

Kele Solution to Issue #2

Allow Kele to build your custom panels. Our panel team double checks your drawings for issues associated with typos or copy-and-paste errors. We ensure that the circuits are hitting the right points. We always review the circuitry before the panel is built. After the panel is assembled, we complete a series of tests to ensure that the product is safe and working appropriately.

Contact Kele today for an estimate – all we need is your panel drawing/wiring diagram and your controllers of choice! Let us take care of the rest! We make the process very simple.

Kele averages a 3-week turn-around time once all components needed for the assembly arrive at Kele.

Find out more about our panel shop capabilities by clicking here!