Hot and Steamy Pig Tails! How to Measure the Pressure of Steam Without Breaking Your Pressure Transmitter

So, in checking the specs, the PTX1-06, can read pressure up to 200 degrees Fahrenheit, like most pressure transmitters in the marketplace. But, steam is steam at 212 degrees Fahrenheit. How’s that going to work?

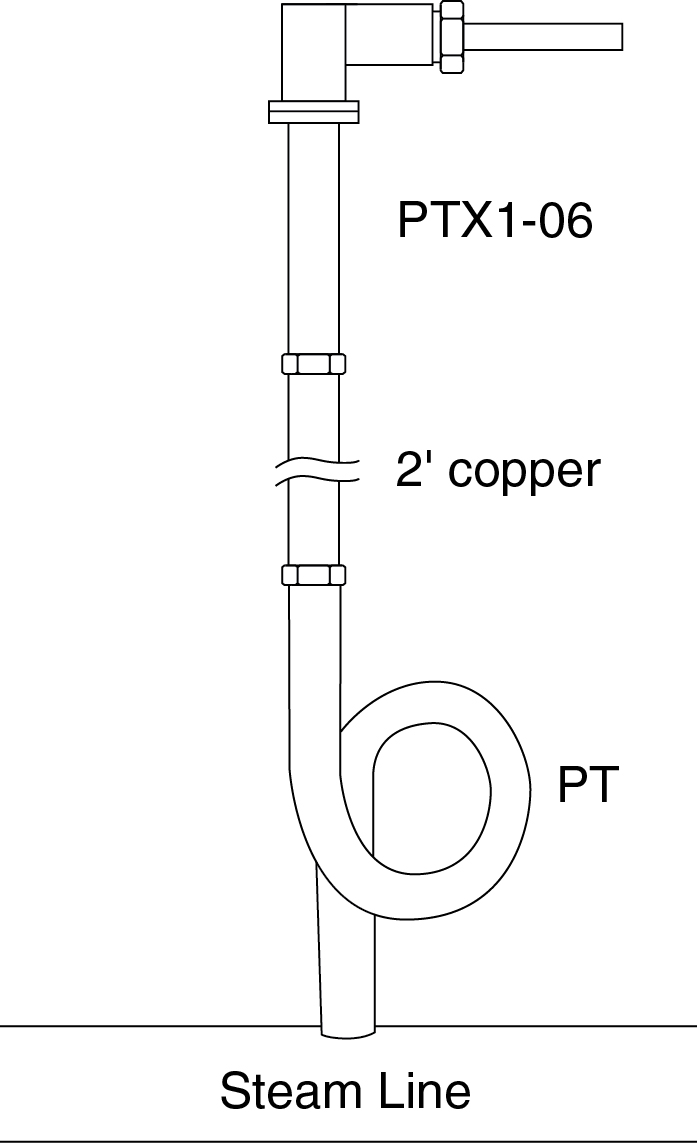

This little piggy says to put a copper extender on a pig tail, and shoot the steam to the side for the best readings. This will also add longevity to the life of your pressure transmitter.

Some installers may try to put the transmitter right over the pig tail, or use a snubber, which is actually designed for water and refrigerants, not steam. We have found that an inexpensive and clever solution is to use a combination of a pig tail with a copper pipe extending to the left or the right of the transmitter. This allows the heat of the steam to dissipate to hot condensate. The steam pressure will push past the water in the pig tail, and still allow you to measure the pressure within the pipe. By allowing the temperature to drop, you will get good readings from the pressure transmitter, while saving the wear and tear on the diaphragm of the pressure transmitter, and keep your warranty valid.

Check out this example:

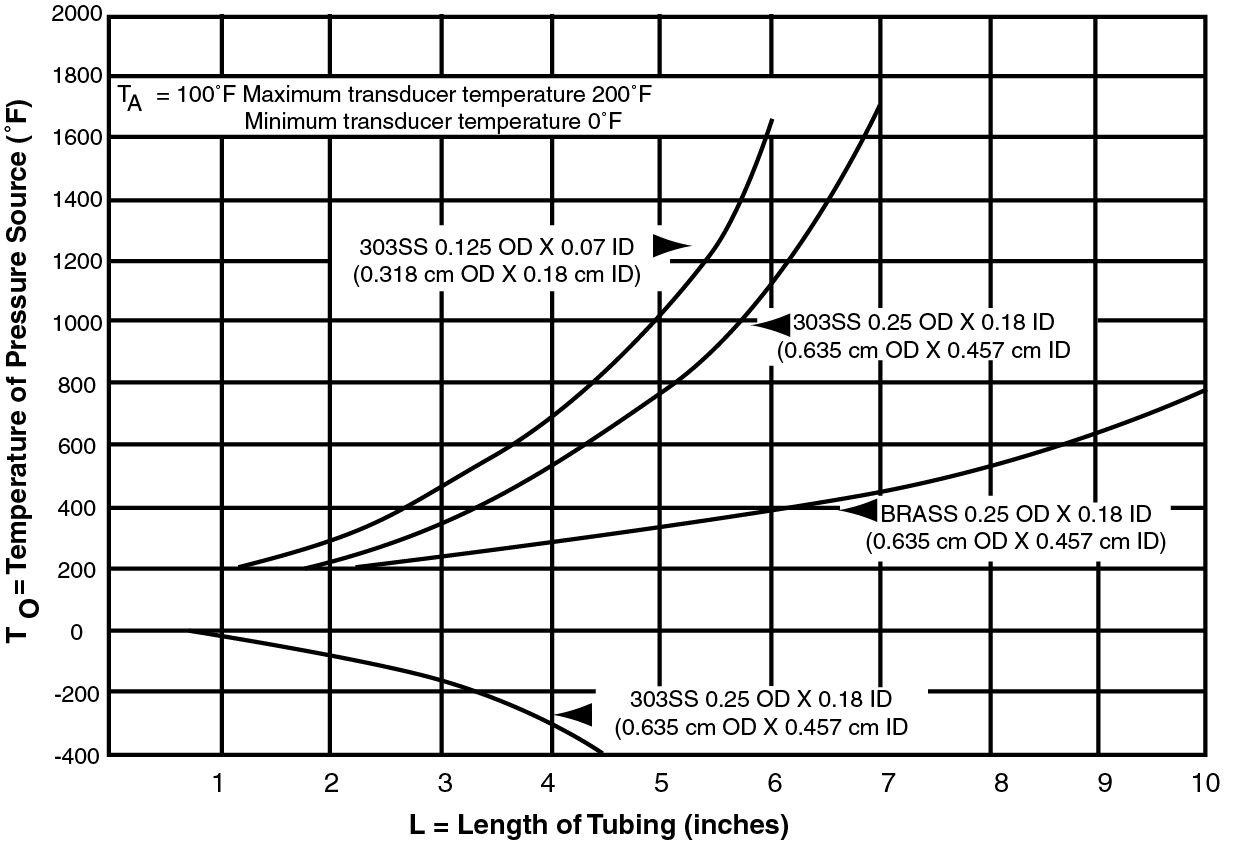

You have a 30 psi steam line, using a PTX1-06 (0-60 psi pressure transmitter) that you need to monitor the pressure in. Screw the pigtail into the steam line. Don’t screw the transmitter directly onto the end of the pigtail. See the chart below to check how long you’ll need the copper pipe to be for your application. In this example, we’d need for it be approximately 2 inches. That will be enough to allow the steam to cool, and be read by the transmitter.

From Data Instruments Reference

- The pressure vessel is insulated to limit radiant heat transfer to the transducer. Thus, the major source of thermal input is via the connecting tube.

- The pressure medium has a coefficient of thermal conductivity less than 0.4 BTU/hr/ft2/ft/°F (6 cal/hr/cm2/cm/°C). This figure encompasses a wide range of liquids and gases.

- The ambient temperature around the transducer is 100°F (37.8°C).

- The heat-transfer rate (convection) from the tubing to still air is 1.44 BTU/ft2/hr°F (1 cal/cm2/hr°C).

If you are blowing through pressure transmitters, they aren’t lasting as long as they should, or giving you false and inaccurate readings, try this, and see if that works better for you.