1/30/19 UPDATE:

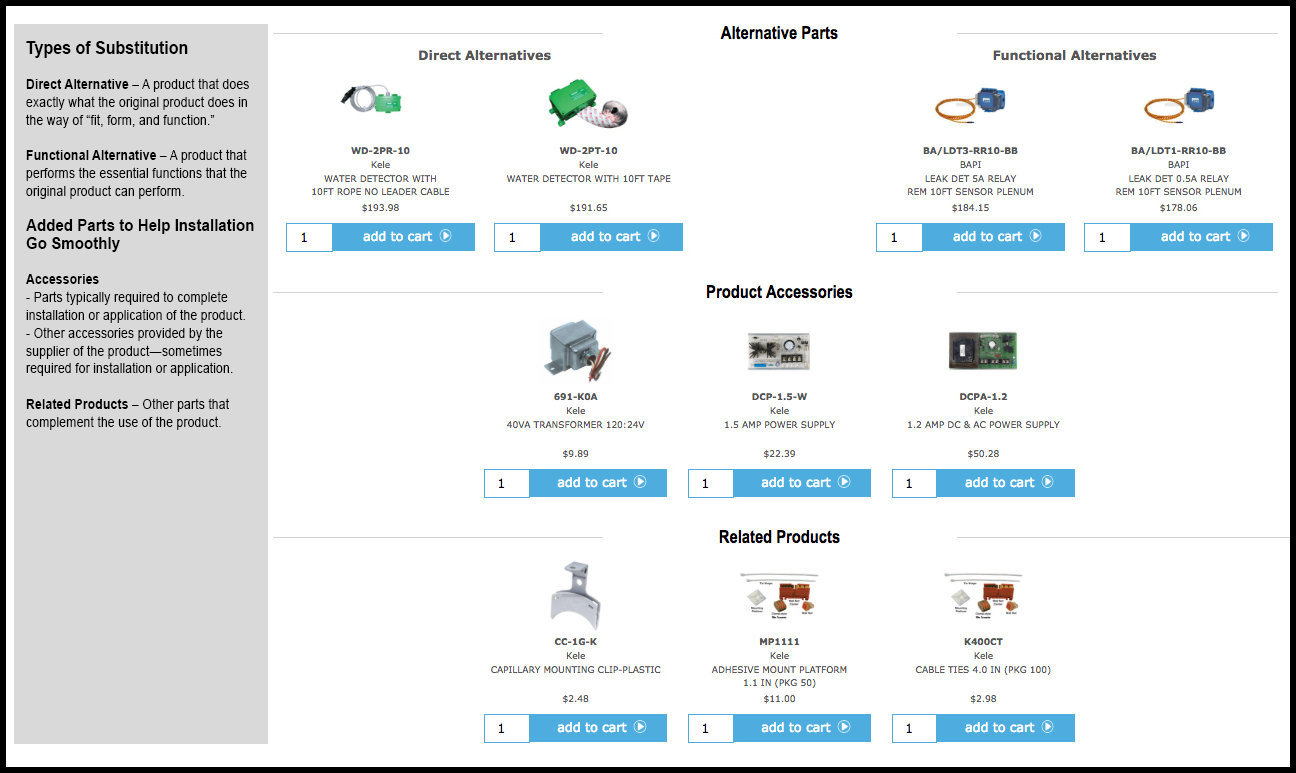

Earlier this month, Kele expanded its product matching solution to nearly 1,000 frequently purchased items. Finding alternatives, accessories, and related parts is now even easier. The update also includes a “Customers Also Bought” section for products that have full cross-reference information. Customers see what other customers typically buy with the product they are viewing. Products without full cross-reference information now feature a “Top Sellers” section containing the top-selling products in the category of the product being viewed. Shop now and see how easy it is to find the products you need.

Kele Introduces Product Matching Solution

Initiative enhances customer user experience and buying process.

Need to quickly find a product accessory? What about an alternative to a tariffed part?

A new feature on kele.com makes this process simple and intuitive. Customers can now view and select accessories, related products, and direct or functional alternatives on the same page/screen as the original product they intend to buy.

Last month, Kele launched phase one of its product matching solution on kele.com across 50 frequently purchased products. A selection of products affected by the recent 25 percent tariff on Chinese imports was also included. As suppliers continue to pass along tariff costs, these product alternatives will be added where relevant.

Although uncommon on most BAS e-commerce platforms, customers will find the user experience familiar and similar to many top-tier consumer e-commerce sites. Customers will soon see what other customers typically buy when buying the product they are currently viewing as well as top sellers overall on kele.com

“What started as an effort to respond to the tariff impact quickly evolved into a bigger opportunity to help our customers win,” said Chief Marketing Officer John Strawn. “The goal is to provide as many relevant solutions as possible and do that as seamlessly as possible.”

In addition to “Customers Also Bought” and “Top Sellers,” phase two of the product matching initiative will expand to 1,000 frequently purchased items. Subsequent phases with more products added will follow.

Regardless of what incorrect signal you have, Kele’s Universal Analog Transducer—the UAT-1—can bridge the gap to move the job forward and keep revenue flowing. Keeping one of these handy devices in your truck will allow you to change any analog input signal (current, voltage, or resistance) into any current or voltage output signal you need. Something as simple as a mismatched signal should not cause a job delay, and Kele’s UAT-1 ensures it will not.

Regardless of what incorrect signal you have, Kele’s Universal Analog Transducer—the UAT-1—can bridge the gap to move the job forward and keep revenue flowing. Keeping one of these handy devices in your truck will allow you to change any analog input signal (current, voltage, or resistance) into any current or voltage output signal you need. Something as simple as a mismatched signal should not cause a job delay, and Kele’s UAT-1 ensures it will not.