HVAC air ducts transfer conditioned air to occupied spaces in a building. In the event of a fire, air ducts can also transfer harmful—and even deadly—smoke, toxic gases, and flames to those same occupied spaces. National and local safety codes and standards address this issue by specifying the use of duct smoke detectors to help prevent injury, panic, and property damage. To prevent the spread and recirculation of smoke and other products of combustion, duct smoke detectors are used to shut off air handling systems, fans, and blowers when necessary. Duct detectors are often connected to the building’s fire alarm system and may also be a part of a control system designed to exhaust smoke to the outside of the building. Duct smoke detectors are not to be used as a substitute for open area protection or early warning detection nor are they a substitute for a building’s regular fire detection system.

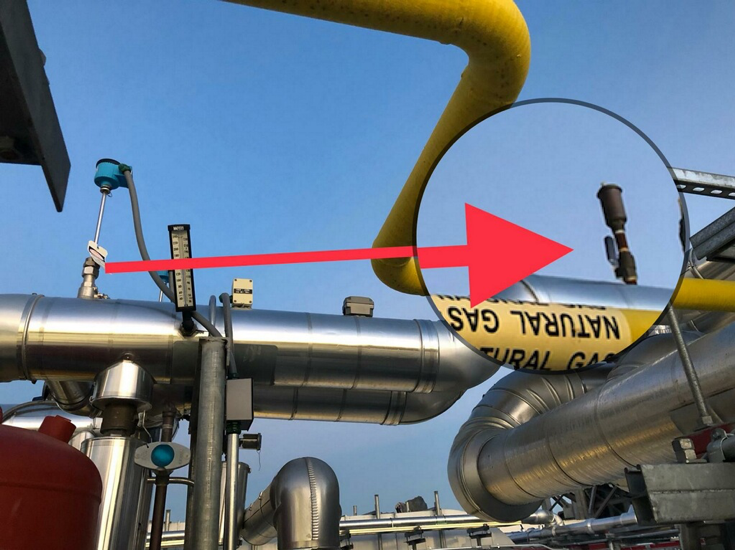

To detect smoke, detectors consisting of a sensor within an enclosure are mounted outside of the duct. Sampling tubes connected to the detector enclosure penetrate and traverse the duct to draw air into the detector, sample it, and then return it

to the air stream. When particles of smoke suspended in the air reach the alarm threshold of the detector, an alarm signal is initiated, and appropriate action can be taken to turn off equipment and alert the building’s fire alarm control panel.

Regardless of the sensing technology used, a duct smoke detector must be installed in a location that will ensure the detector monitors representative samples of

air flowing through the duct. There are several factors to be considered when selecting a detector location in a duct.

- Dilution: Duct smoke detectors will alarm only when combustion particles make up a specified percentage of the sampled air. If circulated air mixes with fresh outside air, the combustion particle concentration can dilute and prevent a detector from sensing a fire condition. To avoid dilution, detectors should be located before fresh air intakes and before the exhaust air output.

- Stratification: Within a duct, air and combustion particles may stratify, preventing proper air sampling. To get a representative air sample, locate the detector between six and 10 duct widths downstream from a bend or other obstruction in the duct.

- Excess humidity: High levels of humidity or condensation within the duct can cause false alarms. Duct smoke detectors should be located a minimum of 10 feet downstream of humidifiers.

- Air filters: Air filters within ducts tend to collect flammable materials

like paper, lint, and trash. Detectors should be installed downstream of filters to detect fires occurring in the filters. Regular filter maintenance is critical since reduced air flow due to clogged filters could prevent correct operation of the duct detector.

- Air velocity: Duct smoke detectors are designed to be used in air handling systems having a certain range of air velocities, usually 500 to 4000 fpm. For applications down to 100 fpm, low-flow technology detectors are available.

Finally, when applying, installing, testing, and maintaining duct smoke detectors, be careful to follow the detector manufacturer’s instructions and adhere to National Fire Protection Association standards National Fire Alarm Code (NFPA 72) and Standard for the Installation of Air Conditioning and Ventilating Systems (NFPA 90A). Copies of the standards can be ordered from www.nfpa.org.

Kele offers a variety of duct smoke detectors and accessories.