Sponsored by Honeywell

The steps and considerations for selecting a Variable Frequency Drive (VFD) are mostly straightforward. In fact, the nameplate on the motor usually provides the essential information, such as voltage and horsepower. Once you determine whether it will be installed indoors or outdoors, and if it needs communication, you’re almost done!

The final question is often the most misunderstood: Is a bypass needed? Why or why not? Let’s look at when you should include a bypass and the different types of bypasses available.

Kele offers five configuration options of the Honeywell Smart VFD.

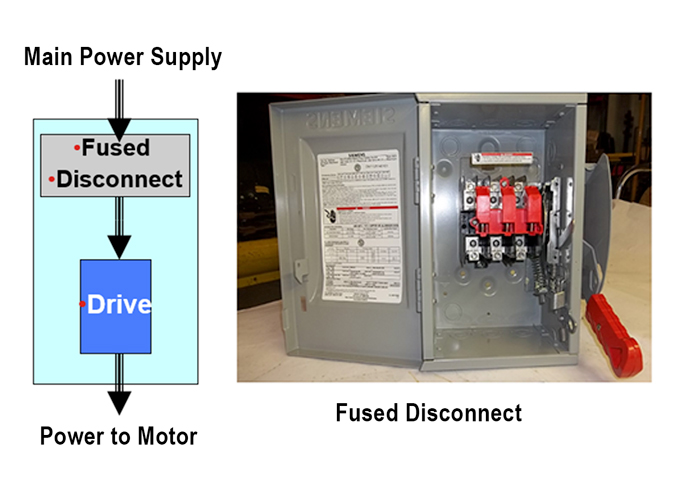

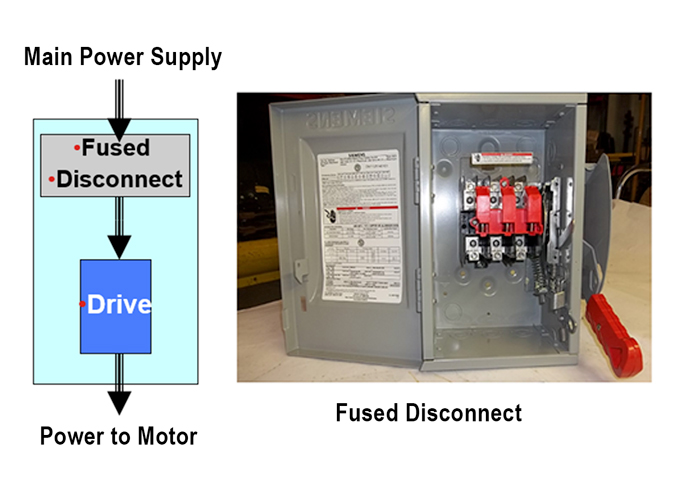

Option 1 is the drive only without any disconnect or bypass. The most common is Option 2, which includes a fused disconnect. These disconnects are required by most electrical codes and a good idea in general. If your electrician does not add a disconnect during installation, you can order one with your new drive.

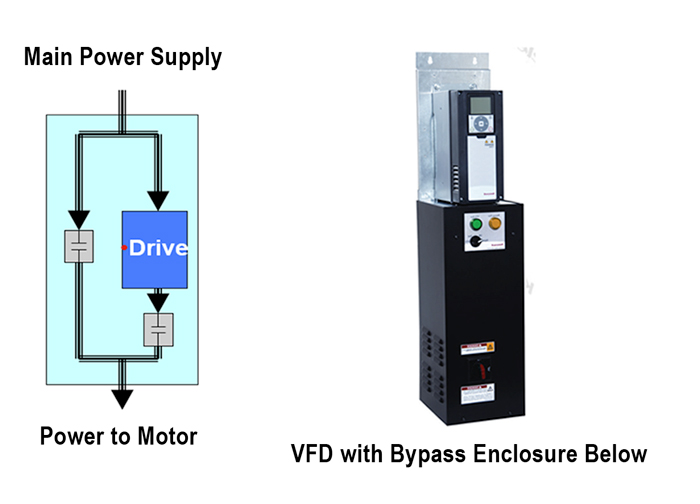

Option 3 is a 2-contactor bypass, and Option 4 is a 3-contactor bypass. Both are designed to minimize system downtime should the VFD fail. These bypasses are ideal for facilities that run 24/7 and can neither afford downtime nor wait for after-hours repairs, such as a big-box store or casino. The difference between the two centers on how easily the failed drive can be replaced. If a VFD fails, the motor it controls will stop running completely.

A 2-contactor bypass allows a technician to flip the switch, bypass the VFD, and the motor will resume running at 100 percent speed. Eventually, the systems should be shut down in order to safely replace the drive.

A 3-contactor bypass adds another contact before the drive that removes power going to the VFD when placed in bypass mode. This means that if the VFD fails, it will be bypassed to maintain motor operation, and the VFD can also be safely removed and replaced with a new unit without interruption in motor operation. This is the main difference between a 2- and 3-contactor bypass:

- With a 2-contactor bypass, you must kill the power before changing the VFD.

- A 3-contactor bypass allows the VFD to be changed while in bypass mode with the motor running.

The final option to consider when selecting a VFD is a 3-contactor bypass with auto changeover. This is typically used only in mission critical spaces that are constantly occupied and cannot tolerate downtime. A hospital operating room is a perfect example. The built-in fault contact on the VFD is monitored by the bypass and automatically bypasses the drive if it begins to have problems. This basically eliminates any loss of service while the VFD is being repaired or replaced. This option is rarely needed in a typical HVAC application.

As you may have guessed, bypasses are complex and can add substantial cost to an already higher-cost device. Typically, a bypass is only added at the request of the customer or if required by a spec. In most cases, a simple fused disconnect provides plenty of protection.

Call Kele with your specific VFD needs, and we will find the right drive for you!

can we safely bypass vfd while motor running with no excessive inrush current?

Hi there! Thanks for your question. It is an interesting one with a few caveats. If your VFD is working and you want to ramp the motor up to 100%, you can do that through the VFD controls without using the bypass. Can you safely bypass a VFD while the motor is running? In theory, yes. Will there be inrush current? Yes, but not as much as if the motor was at a dead stop. Remember that if your motor is being controlled by a VFD with a bypass, and the motor is currently running, then the VFD is working. Since bypasses are used to “bypass” a VFD that has failed and simply run the motor wide open until the VFD can be replaced, you should not need to bypass and probably would not want to bypass the VFD while the motor is running.

In two contactor bypass why contactor is placed at outgoing of Vfd?

What if we eliminate contactor at the outgoing of vfds?

Greetings,

You must isolate the output circuitry of the VFD from the utility feed. If the utility feed goes back into the VFD output the VFD circuitry will be damaged. The VFD output circuitry is designed to drive power out, not have power coming in.

Kele Inc

Hi, I have one question:

at the moment of bypassing there is a mechanical stress on the motor. How is the solution to avoid this stress?

Thanks in advance.

Yes sir, you are correct. It is hard on the motor to switch to bypass and drive it to 100% immediately. If your VFD has died, there isn’t much that can be done to get around that. With that being said, most of the motors today are designed to be able to handle this sudden inrush day in and day out without the soft-start function of a drive. It is hard on them, which is why we put drives on them. On the rare occasion you need to use your bypass, it shouldn’t be enough to do any damage to the motor. I hope this helps.

These Q&A’s are appreciated. I have a VFD that has gone bad. The system is 14 years old. Will a sudden 100% start up really hurt the motor and if so, how long will it take to do any damage?

Thanks

Knight

LCIM

Thank you for your question, Knight.

Our recommendation would be to replace the VFD. To answer your question, yes, the inrush could definitely damage the motor though I can’t tell you how long that would take.

Keep in mind, without the VFD it’s important to monitor the FLA of the motor at startup. Make sure the motor does not exceed its FLA rating on the nameplate of the motor.

Please feel free to contact us if you have any additional questions.

Kele Inc Technical department

When running a bypass, what is the best way to split the power cable so that it goes to the VFD and also goes to the motor? Should a junction box be installed? Or can both of the leads come out of the disconnect switch on the load side?

Dear Kale,

I have a VFD having a capacity of 70-80% load, so can i activate this bypass contactor once load reaches 70-80% load on VFD to meet my demand of 100% load ?

Greeting Nishan,

We would love to help you but we’ll need more information. Please email technicalsales@kele.com or give us a call at 877.826.9045.

Thank you,

Kele Inc

Yes, you can by pass the VFD for smaller rating Motors but in bigger motor there will be jerk. the better way is to by pass the VFD in Stop Conditon