Acquisition is Kele’s third since 2017 and strengthens service to the south-central U.S.

MEMPHIS, Tenn. and DALLAS – Kele, Inc. today announced the acquisition of Temperature Control Systems, Inc. The acquisition expands Kele’s footprint and enhances its ability to serve customers in the south-central United States. Temperature Control Systems, which is headquartered in Dallas with six locations across Texas and Oklahoma, will increase its offering with a broader product line, value-added services, and faster delivery options.

Kele President and CEO Richard Campbell said customers from both companies will realize benefits from the acquisition.

“Two established, value-added distributors joined forces today, and we are excited about the future” said Campbell. “This move demonstrates Kele’s ongoing commitment to transform both how and where we serve customers with industry-leading products and custom solutions.”

Temperature Control Systems is a full-line stocking distributor of commercial HVAC controls and building automation systems. The company serves customers in Texas, Oklahoma, Arkansas, and Louisiana. This marks Kele’s third acquisition in less than two years. In October 2017, Kele initiated its strategic growth plan by acquiring Control Consultants, Inc. (CCI) of Boston and continued last June with the purchase of MIControls, which has locations in Seattle and Portland, Ore.

“For the past two years, Kele has worked to get products closer to our customers for even faster delivery” said Campbell. “We have already seen success in the Northeast and Northwest from the CCI and MIControls branches. Temperature Controls Systems will strengthen our ability to serve customers in the south-central region, and specifically across Texas, Oklahoma, Arkansas, and Louisiana.”

The new entity will operate as a separate brand. Campbell will serve as president and CEO of the combined company. Scott Cross will remain as president of Temperature Controls Systems and lead its locations.

“Temperature Control Systems is excited to join Kele,” said Cross. “Our customers can expect the same value-added service they’ve experienced for more than 40 years. Aligning with Kele will help us meet even more of their needs through additional product lines, services, enhanced order fulfillment, and new digital and eCommerce tools.”

Kele’s acquisition of Temperature Control Systems was effective June 28, 2019. Blank Rome, LLP acted as legal counsel to Kele. Silvermark Partners, LLC acted as financial advisor to Temperature Control Systems, and Wick Phillips, LLP served as its legal counsel.

About Kele, Inc.

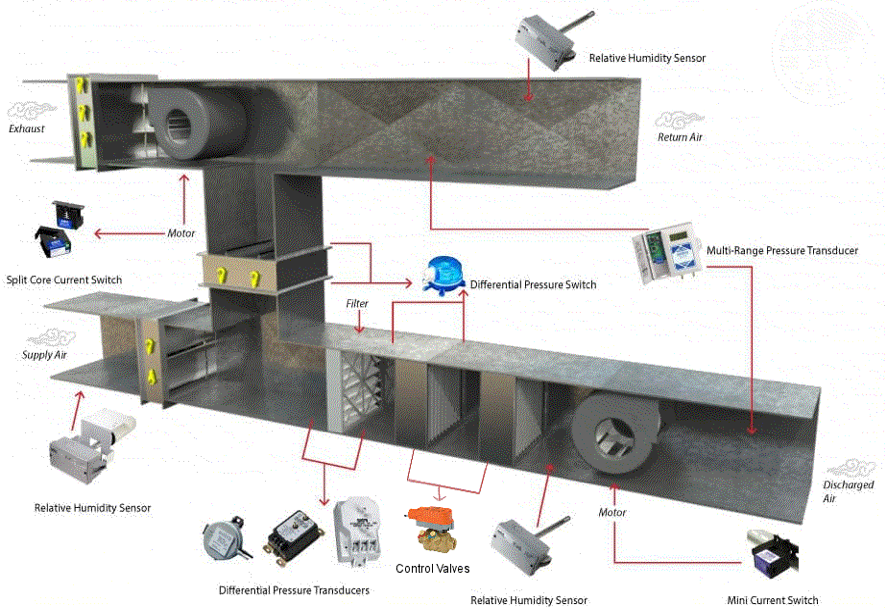

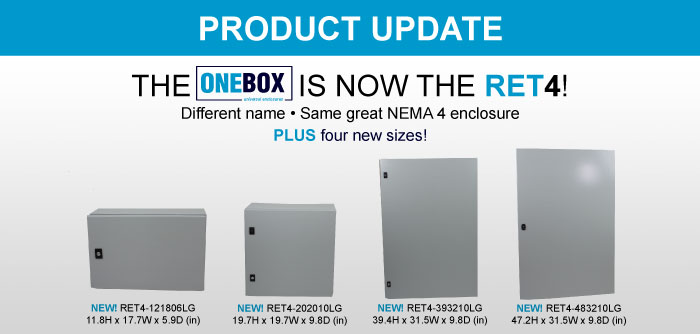

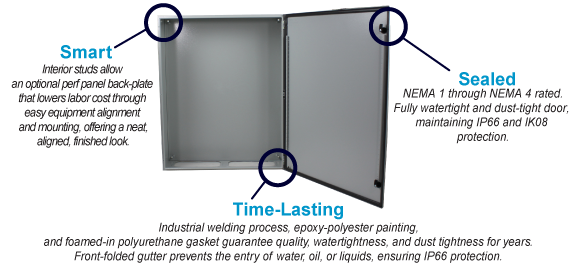

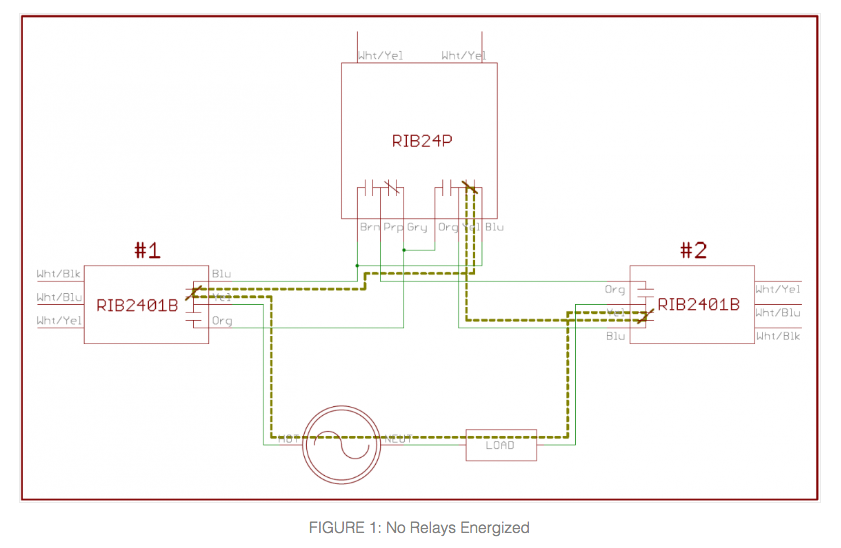

Kele, Inc. is a leading distributor of building automation products and controls solutions globally. Kele serves the $50+ billion building automation systems (BAS) market with more than 300 brands and 1.8 million parts in stock, including sensors, transmitters, switches, gauges, valves, actuators, relays, and more. Kele’s products can be integrated into existing buildings or new construction. Value-added services include custom panel assembly, specialized sourcing, and technical support. Strategically headquartered in America’s logistics hub, Memphis, Tenn., and with regional locations in Boston, Seattle, and Portland, Ore., Kele provides building automation and industrial customers with fast and reliable services. Kele is owned by private equity firm Snow Phipps, LLC. To learn more about Kele, visit kele.com.

About Temperature Control Systems, Inc.

Temperature Control Systems is a full-line stocking distributor of commercial/industrial HVAC controls, burner/boiler controls, and building automation systems. Since 1975, it has grown into a multi-branch, nationwide distributor. Temperature Control Systems prides itself in customer satisfaction, focusing on providing products and best-of-class solutions as well as training. For more information, visit temperaturecontrolsystems.com.